Menu

PVDF Y Strainer

Hayward PVDF YS Series Y-Strainers, available in sizes ranging from 1/2" to 1" (DN15-DN25), crafted to deliver unparalleled performance and reliability in fluid filtration. Constructed with a one-piece moulded body using natural PVDF, these Y-strainers boast exceptional durability and corrosion resistance, making them ideal for a wide range of industrial applications.

PVDF Non-Metallic Y Strainers for High-Purity Chemical Service

-

Hayward Flow Control

More Information »

Hayward Flow Control is not just another thermoplastic flow control manufacturer. As a leading American-engineered solution, Hayward designs, manufactures, tests, and supports its products under one roof, ensuring tight quality control, consistent performance, and full technical traceability.

Backed by decades of experience, Hayward has built an outstanding reputation for robust product design, precise manufacturing, rigorous quality assurance, and responsive technical support. Where cheap imported products often compromise on materials, reliability, and longevity, Hayward focuses on total lifecycle value—fewer failures, less downtime, and safer, more dependable operation. Supported by a committed customer service and engineering team, Hayward Flow Control products are trusted across a wide range of industries and applications worldwide, delivering performance that low-priced copies simply cannot match.

PVDF Y strainers provide robust, non-metallic protection for pipelines handling aggressive chemicals and high-purity process liquids. Manufactured from natural PVDF to ASTM D3222 Type 1 with FPM O-ring seals, Hayward YS Series PVDF strainers offer outstanding corrosion resistance, excellent temperature capability and long service life in demanding environments.

Each PVDF Y strainer features a one-piece injection moulded body and is supplied with a 3/32" perforated PTFE screen as standard, delivering reliable debris removal while maintaining product purity. Monarch Industrial supplies Hayward PVDF Y strainers to Australian and Asia-Pacific customers for duty on corrosive transfer lines, chemical dosing systems and other applications where metal strainers are unsuitable due to corrosion, contamination or maintenance constraints.

| Code | BSP and DIN Fusion Socket |

| YS50015MT3/32 | DN15 PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; BSPT Ends" |

| YS50015MS3/32 | DN15 PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; SDR/DIN SKT Ends" |

| YS50020MT3/32 | DN20 PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; BSPT Ends" |

| YS50020MS3/32 | DN20 PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; SDR/DIN SKT Ends" |

| YS50025MT3/32 | DN25 PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; BSPT Ends" |

| YS50025MS3/32 | DN25 PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; SDR/DIN SKT Ends" |

| Code | NPT and IPS Fusion Socket |

| YS50050T | 1/2" PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; threaded end connections" |

| YS50050S | 1/2" PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; socket end connections" |

| YS50075T | 3/4" PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; threaded end connections" |

| YS50075S | 3/4" PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; socket end connections" |

| YS50100T | 1" PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; threaded end connections" |

| YS50100S | 1" PVDF Y- Strainers w/FPM o-ring; 3/32" perf screen; socket end connections" |

Maximum Flow Rate

The maximum recommended fluid velocity through this Hayward Product is five feet per second (8 ft/s), relative to the connection size fitted.

Higher fluid velocity can result in damage due to the water hammer effect.

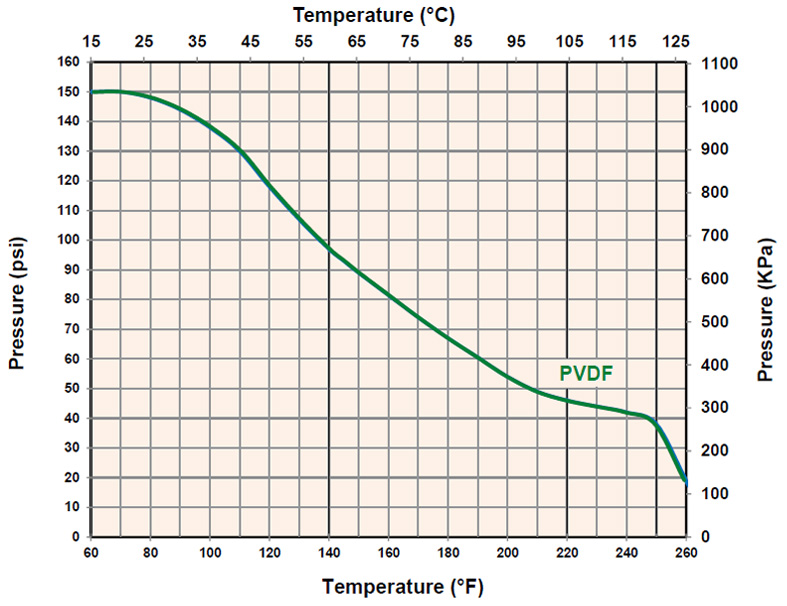

Operating Temperature vs Pressure Chart

The effect of temperature on plastic piping systems must be considered when the systems are initially designed. The pressure rating of plastic systems must be reduced with increasing temperature.

Maximum operating pressure is dependent upon material selection as well as operating temperature.

Before installing any product, consult the product literature for Pressure vs. Temperature curves to determine any operating pressure or temperature limitations.

Monarch Asia Pacific Pty Ltd, © 2026 All Rights Reserved

Release: 26:1:0