Menu

Temporary Truncated Cone Strainer (MTB)

Manufactured in Australia by Monarch

Australian Made - The utilisation of a Truncated Cone Strainer can significantly enhance the Open Area Ratio, thereby maximising its efficiency in various applications. This design not only increases the straining capacity but also allows for greater flexibility in tailoring the strainer to precisely match the requirements of your specific application.

Recognising this diversity of needs, we prioritise close collaboration with our customers to develop tailored solutions that precisely align with their application requirements.

Furthermore, our commitment to quality extends beyond design to encompass material selection, manufacturing processes, and QA procedures. This ensures that the final product not only meets but exceeds performance expectations, delivering superior reliability, durability, and efficiency in real-world applications.

Downloads

-

Open Area Ratio

More Information ▼

When purchasing a cone strainer, one of the foremost design considerations lies in specifying the perforation or mesh size of the straining element.

Typically, screen openings are advised to be roughly half the diameter of the largest allowable particle. This parameter is crucially defined as the size of a particle that can traverse downstream equipment without causing any damage.

A pivotal factor in sizing a cone strainer revolves around the amount of free open area it offers. This metric represents the ratio of the open area through the strainer screen to the cross-sectional area of the pipe.

Tailoring a cone strainer to match your minimum Open Area Ratio requirement is a part of our service. We can provide a comprehensive data sheets and submittal drawings for your consideration.

Commonly requested ratios encompass values exceeding 100%, such as >150%, >200%, >250%, and >300%.

-

Flange Types

More Information ▼

We regularly fabricate flange rings and cone strainers to suit virtually all flange standards including the following. Please specify the flange type when enquiry to ensure clearance between the bolt pattern.

Australian Standard - AS2129Table C, Table D, Table E, Table F, Table G, Table H, Table JBritish Standard - BS10Table D, Table E, Table F, Table G, Table H, Table J, Table KAmerican National Standards Institute (ANSI)ANSI 125, ANSI 125/150, ANSI 300, ANSI 600, ANSI 900, ANSI 1500, ANSI 2500British Standard - BS4504BS4504-6 (PN6), BS4504-10 (PN10), BS4504-16 (PN16), BS4504-25 (PN25), BS4504-40 (PN40, BS4504-64 (PN64), BS4504-100 (PN100)RTJ (Ring Type Joints)Style R Oval, Style RX, Style R Octagonal, Style BX -

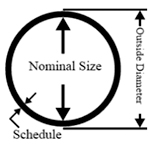

Pipe schedule

More Information ▼

The schedule number on pipe products relates to the thickness of the wall on the pipe. As the number increases, the thicker the wall thickness becomes.

When requesting a quotation please specify the pipe schedule being used. This in important to ensure there is sufficient clearance at the base of the Cone Strainer.

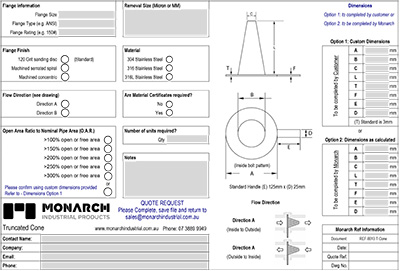

To assist us in providing a quick, accurate quotation, please use the below editable PDF drawings. If you need assistance please call or email our sales team – Ph 07 3889 9949.

INSTRUCTIONS

Download Editable PDF » Complete PDF » Save PDF » Return for costing

List of materials we routinely use

Supported by our Brisbane General Engineering Workshop

- MIG Welding

- TIG Welding

- Rotating Welding Positioner

- Spot Welding Pedestal & Handheld

- Micro Fine Mesh Spot Welding

- Laser Etching

- Centre Lathe

- CNC Plasma Cutter and Hand Held

- Workshop Press

- Swage & Jenny

- Metal passivating & electro polishing system

- 3D Printing

- NC Press brakes

- NC Guillotine

- Folding

- Milling Machine & Drilling etc.

- Rolling

- Cone Rolling Machine

Monarch Asia Pacific Pty Ltd, © 2026 All Rights Reserved

Release: 26:1:0