Menu

Eaton Model 72 Carbon Steel Basket Strainer

Model:

Model 72

Application:

Liquid Filtration

Colour:

Grey

Media:

Stainless Baskets

Eaton Model 72 Simplex Basket Strainers in Carbon Steel are made for general industrial strainer applications and are available in a large variety of connection sizes and strainer basket removal sizes.

Simplex Basket Strainers are designed for applications where temporary interruption of a batch process can be permitted for basket cleaning.

Monarch Strainer are supported by our General Engineering and Strainer Basket Manufacturing Workshop in Brisbane.

Material:

Carbon Steel

Seals:

Buna-N/Nitrile (Standard), other materials available on request

Basket:

1 off Basket in Stainless Steel

Pressure:

150#

Lid Yoke Assembly:

Zinc Plated and Carbon Steel

Options:

Differential Pressure Indicator

Magnets

Magnets

Connections:

ANSI 150# and NPT

Flange Sizes:

1", 1-1/2", 2", 2-1/2", 3", 4",5", 6", 8"

NPT Threaded Sizes:

3/8", 1/2", 3/4", 1", 1-1/2", 2", 2-1/2", 3"

Basket Options

Perforated (Imperial)

1/32", 3/64", 1/16", 1/8", 5/32", 3/16", 1/4", 3/8", 1/2"

Perforated (mm)

0.5, 0.8, 1, 1.5, 2, 3, 4, 5, 6, 8, 10, 12, 15mm

Fine Mesh (Mesh Sizes)

20, 40, 60, 80, 100, 150, 200, 325, 400 Mesh

Fine Mesh (Micron Sizes µ)

80, 100, 130, 150, 190, 210, 260, 310, 401, 530, 570, 600, 810, 900 Micron

Hollander Weave (Micron Sizes µ)

5/14, 10/18, 15/26, 25/38, 35/45, 55/75

(5 = Micron Nominal / 14 = Micron Absolute)

One of the most important design considerations when purchasing a strainer is specifying the perforation or mesh size of the straining element. If the removal size required is not listed, please contact our sales team.

Factors to be Taken Account of when Selecting a Strainer:

- Fluid type

- Flow rate

- Viscosity

- Temperature – operating and design

- Pressure – operating and design

- Degree of filtration required

- Connection type i.e. flanged PN16, ASA150, screwed BSP, NPT

- Any special requirements i.e. heating jacket, magnets, mounting brackets, dp indicator/switch etc.

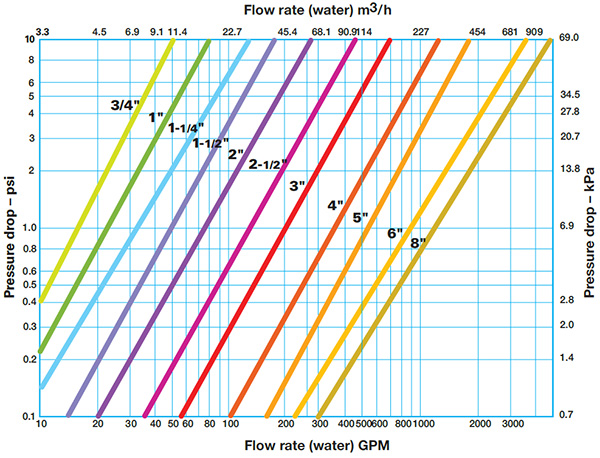

For most applications the clean differential pressure should be less than 0.2 bar (3 psi).

The chart is for water (1cSt) flowing through a filter with an element coarser than 1mm perforations.

Please refer to brochure for viscosity and mesh basket correction factors.

The chart is for water (1cSt) flowing through a filter with an element coarser than 1mm perforations.

Please refer to brochure for viscosity and mesh basket correction factors.

Monarch Asia Pacific Pty Ltd, © 2026 All Rights Reserved

Release: 26:1:0