Menu

GFPP (Black) Simplex Basket Strainer

Industrial GFPP basket strainers are used when the process flow can be interrupted to clean the strainer basket. The Hayward design has many user-friendly features and requires no tools to safely access the strainer basket chamber.

The oversized handles on the basket chamber cover minimize the effort required for opening and closing the basket chambers. The tab style vent and drain ports have a capture o-ring design and thus do not require tools to remove.

The true union connections simplify installation and, specifically for glued socket connections, enable installation/removal without cutting the pipeline.

- Stainless Steel Strainer Baskets

- Pressure Differential Gauge and Switch

- Baskets Available with Mesh Liner

- True Union

- Ergonomic Hand-Removable Cover

- In-Line or Loop Connections

- External Cover Threads

- Integral Flat Mounting Bases

- GFPP Basket Standard Standard

| Code | BSP and PN10 Flanged |

| SB4015MT | DN15 Black GFPP Simplex Basket Strainer w/FPM o-rings; BSPT End Connections |

| SB4020MT | DN20 Black GFPP Simplex Basket Strainer w/FPM o-rings; BSPT End Connections |

| SB4025MT | DN25 Black GFPP Simplex Basket Strainer w/FPM o-rings; BSPT End Connections |

| SB4025MF | DN25 Black GFPP Simplex Basket Strainer w/FPM o-rings; PN10 FLGD End Connections |

| SB4032MT | DN32 Black GFPP Simplex Basket Strainer w/FPM o-rings; BSPT End Connections |

| SB4032MF | DN32 Black GFPP Simplex Basket Strainer w/FPM o-rings; PN10 FLGD End Connections |

| SB4040MT | DN40 Black GFPP Simplex Basket Strainer w/FPM o-rings; BSPT End Connections |

| SB4040MF | DN40 Black GFPP Simplex Basket Strainer w/FPM o-rings; PN10 FLGD End Connections |

| SB4050MT | DN50 Black GFPP Simplex Basket Strainer w/FPM o-rings; BSPT End Connections |

| SB4050MF | DN50 Black GFPP Simplex Basket Strainer w/FPM o-rings; PN10 FLGD End Connections |

| SB4065MT | DN65 Black GFPP Simplex Basket Strainer w/FPM o-rings; BSPT End Connections |

| SB4065MF | DN65 Black GFPP Simplex Basket Strainer w/FPM o-rings; PN10 FLGD End Connections |

| SB4080MT | DN80 Black GFPP Simplex Basket Strainer w/FPM o-rings; BSPT End Connections |

| SB4080MF | DN80 Black GFPP Simplex Basket Strainer w/FPM o-rings; PN10 FLGD End Connections |

| SB4100MT | DN100 Black GFPP Simplex Basket Strainer w/FPM o-rings; BSPT End Connections |

| SB4100MF | DN100 Black GFPP Simplex Basket Strainer w/FPM o-rings; PN10 FLGD End Connections |

| Code | NPT and ANSI Flanged |

| SB4050T | 1/2" Black GFPP Simplex Basket Strainer w/FPM o-rings; threaded end connections" |

| SB4075T | 3/4" Black GFPP Simplex Basket Strainer w/FPM o-rings; threaded end connections" |

| SB4100T | 1" Black GFPP Simplex Basket Strainer w/FPM o-rings; threaded end connections" |

| SB4100F | 1" Black GFPP Simplex Basket Strainer w/FPM o-rings; flanged end connections" |

| SB4125T | 1-1/4" Black GFPP Simplex Basket Strainer w/FPM o-rings; threaded end connections" |

| SB4125F | 1-1/4" Black GFPP Simplex Basket Strainer w/FPM o-rings; flanged end connections" |

| SB4150T | 1-1/2" Black GFPP Simplex Basket Strainer w/FPM o-rings; threaded end connections" |

| SB4150F | 1-1/2" Black GFPP Simplex Basket Strainer w/FPM o-rings; flanged end connections" |

| SB4200T | 2" Black GFPP Simplex Basket Strainer w/FPM o-rings; threaded end connections" |

| SB4200F | 2" Black GFPP Simplex Basket Strainer w/FPM o-rings; flanged end connections" |

| SB4250T | 2-1/2"Black GFPP Simplex Basket Strainer w/FPM o-rings; threaded end connections" |

| SB4250F | 2-1/2" Black GFPP Simplex Basket Strainer w/FPM o-rings; flanged end connections" |

| SB4300T | 3" Black GFPP Simplex Basket Strainer w/FPM o-rings; threaded end connections" |

| SB4300F | 3" Black GFPP Simplex Basket Strainer w/FPM o-rings; flanged end connections" |

| SB4400T | 4" Black GFPP Simplex Basket Strainer w/FPM o-rings; threaded end connections" |

| SB4400F | 4" Black GFPP Simplex Basket Strainer w/FPM o-rings; flanged end connections" |

| Connection | Velocity | Approx Flow Rate lt/hr | |

| DN15 | 1/2" | 5 feet/sec | 870 |

| DN20 | 3/4" | 5 feet/sec | 1,580 |

| DN25 | 1" | 5 feet/sec | 2,600 |

| DN32 | 1-1/4" | 5 feet/sec | 4,325 |

| DN40 | 1-1/2" | 5 feet/sec | 6,320 |

| DN50 | 2" | 5 feet/sec | 10,560 |

| DN65 | 2-1/2" | 5 feet/sec | 15,100 |

| DN80 | 3" | 5 feet/sec | 23,050 |

| DN100 | 4" | 5 feet/sec | 40,850 |

Body/Basket Sizes

The Hayward SB Strainer is based on 4 standard physical body and basket sizes.

- Body size 1 can be fitted with 1/2", 3/4" or 1" connections.

- Body size 2 can be fitted with 1-1/4", 1-1/2" or 2" connections.

- Body size 4 can be fitted with 2-1/2", 3" or 4" connections.

- Body size 6 can be fitted with 6" or 8" connections.

Maximum Flow Rate

The maximum recommended fluid velocity through this Hayward Product is five feet per second (5 ft/s), relative to the connection size fitted. Higher fluid velocity can result in damage due to the water hammer effect.

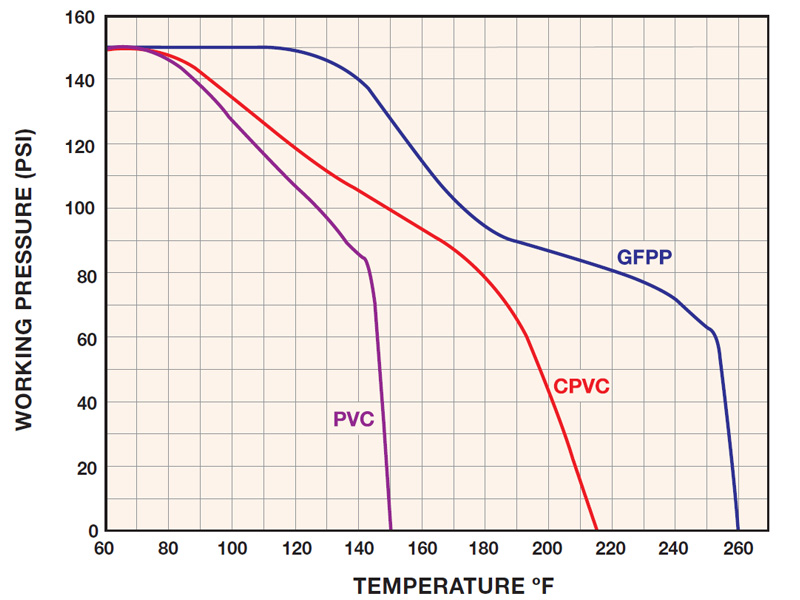

Operating Temperature vs Pressure Chart

The effect of temperature on plastic piping systems must be considered when the systems are initially designed. The pressure rating of plastic systems must be reduced with increasing temperature.

Maximum operating pressure is dependent upon material selection as well as operating temperature.

Before installing any product, consult the product literature for Pressure vs. Temperature curves to determine any operating pressure or temperature limitations.

Basket Options

Monarch Asia Pacific Pty Ltd, © 2026 All Rights Reserved

Release: 26:1:0