Menu

PVC Simplex Basket Strainer

Introducing our Industrial Simplex Basket Liquid Strainer, meticulously crafted from PVC (Polyvinyl Chloride) material, engineered to deliver exceptional performance and reliability in liquid filtration processes across various industries.

Designed for heavy-duty industrial applications, this strainer is the epitome of durability and efficiency. The PVC material offers excellent chemical resistance, ensuring compatibility with a wide range of fluids, including corrosive liquids. Its robust construction guarantees long-term performance even in demanding environments.

Featuring a simplex basket design, this strainer simplifies operation and maintenance. The large-capacity basket provides ample filtration area, effectively capturing contaminants and debris from the liquid stream. This helps maintain equipment integrity and prolongs the lifespan of downstream components.

With precision-engineered perforations on the basket surface, this strainer ensures efficient filtration while allowing for smooth liquid flow, minimizing pressure drop and maximizing system efficiency.

Installation versatility is key, and our strainer offers multiple connection options to seamlessly integrate into your existing pipeline system, facilitating quick and hassle-free setup.

Whether you're in the chemical processing, water treatment, or food and beverage industries, our Industrial Simplex Basket Liquid Strainer in PVC material is your trusted solution for superior liquid filtration performance, durability, and peace of mind. Upgrade your filtration system today and experience the difference.

- Stainless Steel Strainer Baskets

- Pressure Differential Gauge and Switch

- Baskets Available with Mesh Liner

- True Union

- Ergonomic Hand-Removable Cover

- In-Line or Loop Connections

- External Cover Threads

- Integral Flat Mounting Bases

- PVC Basket Standard Standard

| Code | PN10 Flanged (FPM-Viton) |

| SB1600MFT | DN150 PVC Simplex Basket Strainer w/FPM o-rings; PN10 FLGD End Connections |

| SB1800MFT | DN200 PVC Simplex Basket Strainer w/FPM o-rings; PN10 FLGD End Connections |

| Code | PN10 Flanged (FPM-EPDM) |

| SB1600MFTE | DN150 PVC Simplex Basket Strainer w/EPDM o-rings; PN10 FLGD End Connections |

| SB1800MFTE | DN200 PVC Simplex Basket Strainer w/EPDM o-rings; PN10 FLGD End Connections |

| Code | ANSI Flanged (FPM-Viton) |

| SB1600FT | 6" PVC Simplex Basket Strainer w/FPM o-rings; flanged end connections" |

| SB1800FT | 8" PVC Simplex Basket Strainer w/FPM o-rings; flanged end connections" |

| Code | ANSI Flanged (EPDM) |

| SB1600FTE | 6" PVC Simplex Basket Strainer w/EPDM o-rings; flanged end connections" |

| SB1800FTE | 8" PVC Simplex Basket Strainer w/EPDM o-rings; flanged end connections" |

| Connection | Velocity | Approx Flow Rate lt/hr | |

| DN150 | 6" | 5 feet/sec | 92,690 |

| DN200 | 8" | 5 feet/sec | 161,800 |

Body/Basket Sizes

The Hayward SB Strainer is based on 4 standard physical body and basket sizes.

- Body size 1 can be fitted with 1/2", 3/4" or 1" connections.

- Body size 2 can be fitted with 1-1/4", 1-1/2" or 2" connections.

- Body size 4 can be fitted with 2-1/2", 3" or 4" connections.

- Body size 6 can be fitted with 6" or 8" connections.

Maximum Flow Rate

The maximum recommended fluid velocity through this Hayward Product is five feet per second (5 ft/s), relative to the connection size fitted. Higher fluid velocity can result in damage due to the water hammer effect.

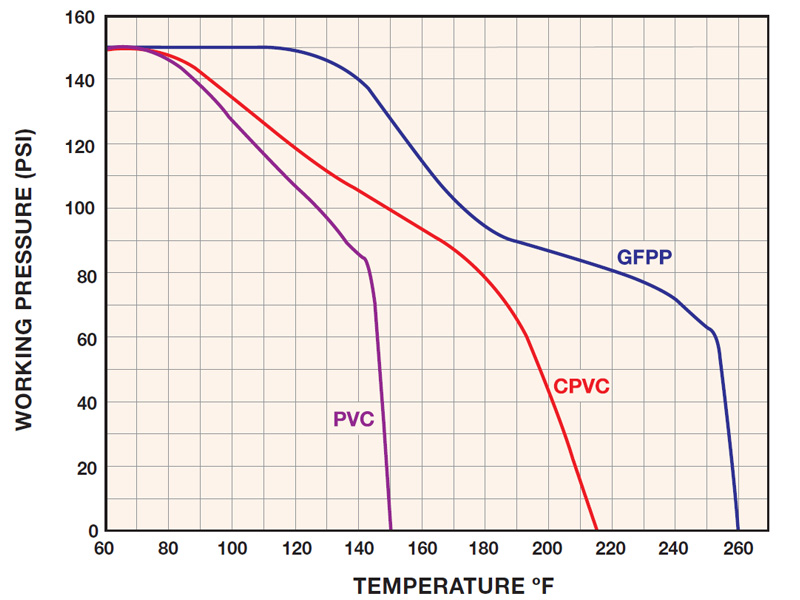

Operating Temperature vs Pressure Chart

The effect of temperature on plastic piping systems must be considered when the systems are initially designed. The pressure rating of plastic systems must be reduced with increasing temperature.

Maximum operating pressure is dependent upon material selection as well as operating temperature.

Before installing any product, consult the product literature for Pressure vs. Temperature curves to determine any operating pressure or temperature limitations.

Basket Options

Monarch Asia Pacific Pty Ltd, © 2026 All Rights Reserved

Release: 26:1:0