Menu

CW Series String Wound Cartridge

Series:

CW

Application:

Liquid Filtration

Manufacturer:

Feature-Tec Filtration

End Types:

Various, see Ordering Information

CW Series string wound filter cartridges are designed for reliable, high-pressure depth filtration of liquids (and suitable gas streams) where consistent particle removal and long service life are required. A specially designed, patented internal frame with a spiral-welded structure helps maintain cartridge rigidity and reduces the risk of deformation. This rigid “cellular” construction minimises bypass (side leakage), reduces pressure drop, increases contaminant holding capacity, and supports high filtration accuracy.

Why choose CW string wound cartridges?

- High-pressure capable design with a rigid internal support structure

- True depth filtration: compact inner layers with more open outer layers for high dirt-holding capacity

- Gradient pore structure for consistent retention and efficient impurity removal

- Wide chemical compatibility with multiple media, core and seal options

- High efficiency (up to ~90%) depending on media and rating

Micron Removal Sizes:

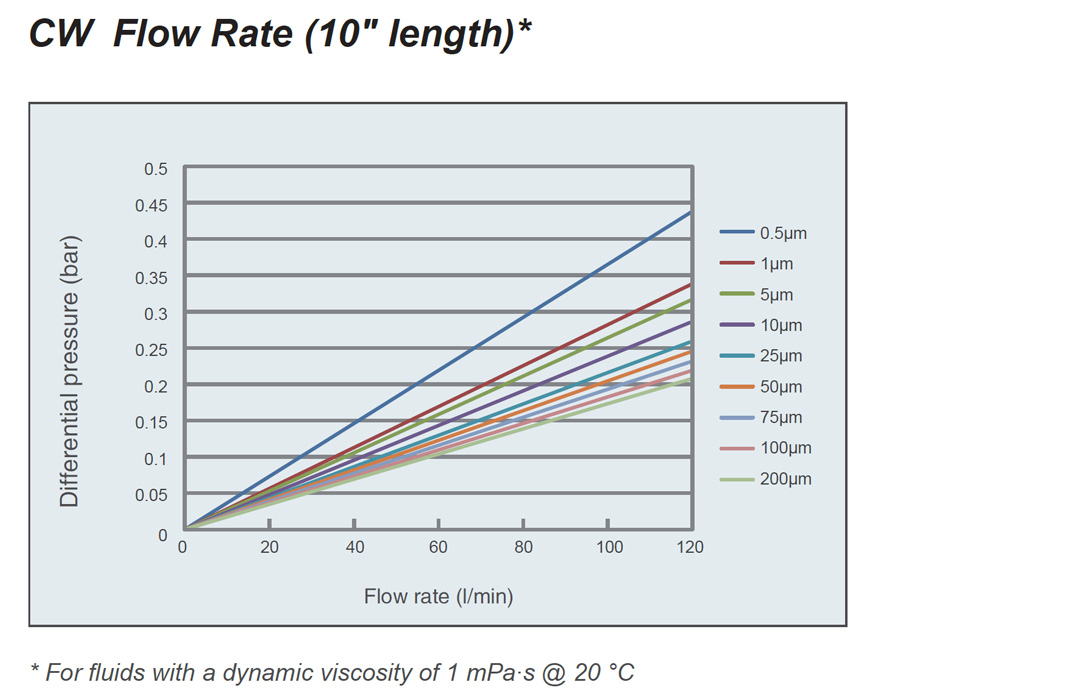

0.5, 1, 5, 10, 25, 50, 75, 100, 150 and 200 Micron

Cartridge Lengths:

10", 20", 30", 40", 50", 60", 70" and 80"

Materials:

Bleached Cotton, Polypropylene (Food & Bev), Polypropylene (industrial), Nylon, Polyester, Fiberglass, Polyphenylene Sulfide (PPS)

Inner Cores:

Tinned steel, Polypropylene, Stainless Steel 304, 304L, 316L

Max. Operating Temperature:

With steel core

Polypropylene: < 93°C (200°F)

Cotton: < 120°C (248°F)

Nylon: < 130°C (266°F)

Polyester: < 130°C (266°F)

Fiber glass: < 450°C (842°F)

PPS: < 190°C (374°F)

With PP core

Cotton: < 80°C (176°F)

Polypropylene: < 80°C (176°F)

Polypropylene: < 93°C (200°F)

Cotton: < 120°C (248°F)

Nylon: < 130°C (266°F)

Polyester: < 130°C (266°F)

Fiber glass: < 450°C (842°F)

PPS: < 190°C (374°F)

With PP core

Cotton: < 80°C (176°F)

Polypropylene: < 80°C (176°F)

Recommended Change Out DP:

2 - 3 bar @ 80% of Maximum Allawable temperature

Maximum Differential Pressure (DP):

≤5 bar (72.5 psi)

High DP preesure units available on request

High DP preesure units available on request

O Ring Materials:

Buna N, Silicone, EPDM, Viton, FEP/Viton

Outside Diamters:

2" (50.8mm), 2.375" (60.3mm), 2.5" (63.5mm) , 3" (76.2mm), 4.5" (114.3mm)

inside Diamters:

1.1" (30mm)

Code Example: CW FG 1 R 30 S 6 V

Series: (CW)

CW String Wound

Material: (FG)

BC = Bleached cotton

FP = Polypropylene (F & B)

EP = Polypropylene (Industrial)

NY = Nylon

PE = Polyester

FG = Fiberglass

PS = PPS

FP = Polypropylene (F & B)

EP = Polypropylene (Industrial)

NY = Nylon

PE = Polyester

FG = Fiberglass

PS = PPS

Micron Rating: (1)

05 = 0.5 micron

1 = 1 micron

5 = 5 micron

10 = 10 micron

25 = 25 micron

50 = 50 micron

75 = 75 micron

100 = 100 micron

150 = 150 micron

200 = 200 micron

1 = 1 micron

5 = 5 micron

10 = 10 micron

25 = 25 micron

50 = 50 micron

75 = 75 micron

100 = 100 micron

150 = 150 micron

200 = 200 micron

Outer Diameter: (R)

T = 2" (50.8 mm)

F = 2.375" (60.3 mm)

R = 2.5" (63.5 mm)

P = 3" (76.2 mm)

B = 4.5" (114.3 mm)

F = 2.375" (60.3 mm)

R = 2.5" (63.5 mm)

P = 3" (76.2 mm)

B = 4.5" (114.3 mm)

Cartridge Length: (30)

10 = 10" (254 mm)

20 = 20" (508 mm)

30 = 30" (762 mm)

40 = 40" (1016 mm)

50 = 50" (1270 mm)

60 = 60" (1524 mm)

70 = 70" (1778 mm)

80 = 80" (2032 mm)

20 = 20" (508 mm)

30 = 30" (762 mm)

40 = 40" (1016 mm)

50 = 50" (1270 mm)

60 = 60" (1524 mm)

70 = 70" (1778 mm)

80 = 80" (2032 mm)

Core material: (S)

Z = Tinned steel

E = Stainless Steel 304

F = Stainless Steel 304L

S = Stainless Steel 316L

P = Polypropylene

E = Stainless Steel 304

F = Stainless Steel 304L

S = Stainless Steel 316L

P = Polypropylene

End Configuration: (6)

2 = 226 Flat, Single Open End

3 = 222 Flat, Single Open End

4 = 226 Fin, Single Open End

6 = 222 Fin, Single Open End

7 = Double Open End

3 = 222 Flat, Single Open End

4 = 226 Fin, Single Open End

6 = 222 Fin, Single Open End

7 = Double Open End

O Ring: (V)

B = Buna N

S = Silicone

E = EPDM

V = Viton

C = FEP/Viton

U = None

S = Silicone

E = EPDM

V = Viton

C = FEP/Viton

U = None

Notes

Summary of code: CWFG1R30S6V

CW = CW String Wound

FG = Fiberglass material

1 = 1 Micron Removal

R = 2.5" (63.5 mm) Diameter

30 = 30" Length

S = 316L Core Material

6 = 222 Fin, Single Open End Types

V = Viton O Rings

CW = CW String Wound

FG = Fiberglass material

1 = 1 Micron Removal

R = 2.5" (63.5 mm) Diameter

30 = 30" Length

S = 316L Core Material

6 = 222 Fin, Single Open End Types

V = Viton O Rings

Monarch Asia Pacific Pty Ltd, © 2026 All Rights Reserved

Release: 26:1:0