Menu

Pleated Filter Cartridge SC-N66 Series

SC N66 Filter Cartridges are sterile liquid filter cartridges manufactured with an inherently hydrophilic Nylon 66 membrane, designed for bio-burden reduction and final filtration of a wide range of pharmaceutical and biological solutions.

The SC N66 range combines naturally water-wettable Nylon 66 membrane performance with low pressure drop and high flow rates to support reliable sterile filtration and long service life. For enhanced retention, an optional modified Nylon 66 membrane with positive-charged Zeta particles is available—helping improve capture of very fine contaminants, especially endotoxins.

Each cartridge is produced under controlled quality practices, including bacterial quantitative retention testing to ASTM F838 (Brevundimonas diminuta), 100% integrity testing during manufacturing, and full traceability via unique serial number. Typical applications include food & beverage, medical and health services, pharmaceuticals, and life science processes.

4.0 bar (58 psi) at 60°C

2.4 bar (35 psi) at 80°C

6.9 bar (100 psi) at 25°C

4.0 bar (58 psi) at 60°C

2.4 bar (35 psi) at 80°C

Reverse

3.0 bar (44 psi) at 25°C

1.0 bar (15 psi) at 80°C

≥ 1.2 bar (17 psi), air, 1.2+0.45μm

≤ 20 ml/min at 2.75 bar (40psi), water wetted, 0.45+0.22μm

≤ 18 ml/min at 1.0 bar (15psi), water wetted, 1.2+0.45μm

0.84m²/ Ø69-10" 1.2+0.45μm

Sterilization Grade

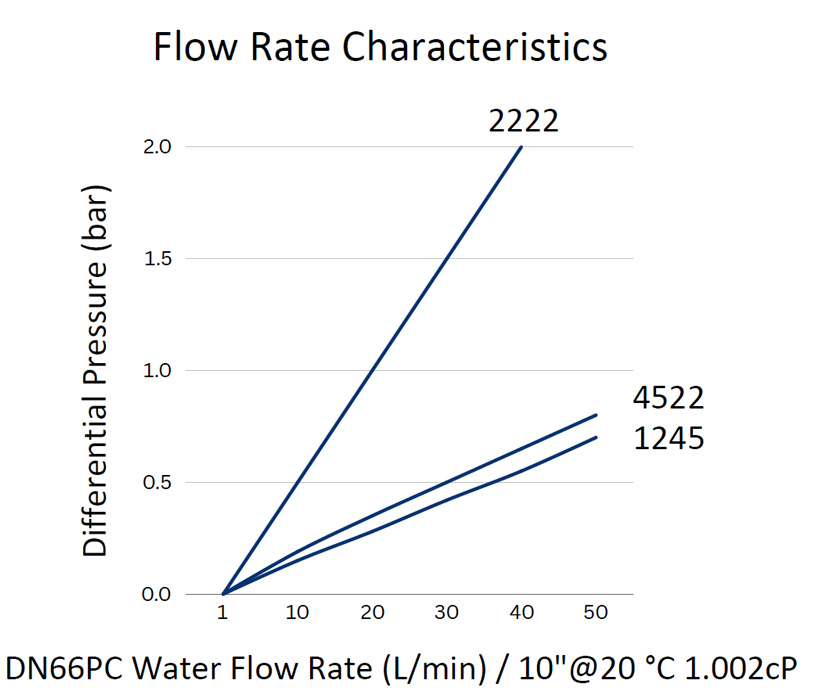

0.22+0.22μm (2222)

0.45+0.22μm (4522)

1.2+0.45μm (1245)

Code Example: SC N66 10 0.22 FN22 V

20 = 20"

30 = 30"

FN22 = 222 Fin, Single Open End

E = EPDM

V = Viton

CARTRIDGE FILTRATION

-

1. What is Maximum Differential Pressure?

Maximum Differential Pressure is the highest pressure difference between the inlet and outlet of a membrane cartridge filter that the cartridge can safely withstand without damage (media collapse, pleat deformation, end-cap failure, or bypass).

- Why it matters: Exceeding Max DP can permanently damage the membrane and compromise sterile performance.

-

How it’s applied: Max DP is typically specified for:

- Forward flow (normal filtration direction)

- Reverse flow (backflow during upset or incorrect installation)

- Sometimes separately for liquid service vs gas/air service, and for operating vs cleaning/steam sterilisation conditions.

-

2. What is Bubble Point?

Bubble Point is an integrity test concept: it is the minimum gas pressure required to force a continuous stream of bubbles through a fully wetted membrane (in contact with a wetting liquid).

-

What it indicates: Bubble Point is related to the largest pore size in the membrane. If the bubble point is too low, it can indicate:

- membrane damage,

- improper wetting,

- incorrect cartridge grade, or.

- sealing/bypass issues..

- Why it matters for sterile filtration: It’s widely used as a quick verification that the membrane is intact and capable of achieving its rated retention (sterile performance), when performed per the manufacturer’s procedure.

-

What it indicates: Bubble Point is related to the largest pore size in the membrane. If the bubble point is too low, it can indicate:

-

3. What is Diffusion Flow?

Diffusion Flow (also called diffusive flow) is the measured gas flow rate that passes through a fully wetted, intact membrane during an integrity test below the bubble point pressure.

- What’s happening physically: Gas dissolves into the wetting liquid within the pores and migrates through the membrane—this is normal and expected at pressures below bubble point.

-

What it indicates: Diffusion flow should be within a specified limit for the filter grade and test conditions. If diffusion flow is too high, it may indicate:

- a damaged membrane,

- incomplete wetting,

- wrong wetting fluid,

- temperature effects, or

- leakage at seals/housing.

-

4. What is Effective Filtration Area (EFA)?

Effective Filtration Area is the usable membrane surface area inside the cartridge that is actually available for filtration (typically expressed in m² or ft²).

-

Why it matters: Higher EFA generally means:

- a damaged membrane,

- higher flow at a given pressure drop, and/or

- longer service life before the filter blocks (more contaminant holding capacity).

- Important note: Two cartridges of the same length can have different EFA depending on pleat count, pleat geometry, membrane type, and construction—so EFA is a key comparison spec for sizing and performance.

-

Why it matters: Higher EFA generally means:

Monarch Asia Pacific Pty Ltd, © 2026 All Rights Reserved

Release: 26:1:0